About this article

Categories

The printing industry is vast and fascinating, extending far back in history through many years of development. In this guide, we will go through all the printing methods and provide a comprehensive insight into the various processes.

Although there is a multitude of printing techniques, each with its own characteristics and advantages, there are four main categories: letterpress, intaglio, planography, and serigraphy. In some contexts, a fifth printing method, digital printing, is also mentioned.

Letterpress is considered the oldest print method in the world, invented in the 15th century by Johannes Gutenberg. With his invention, Gutenberg revolutionized the book market, as it became possible to print books in larger editions.

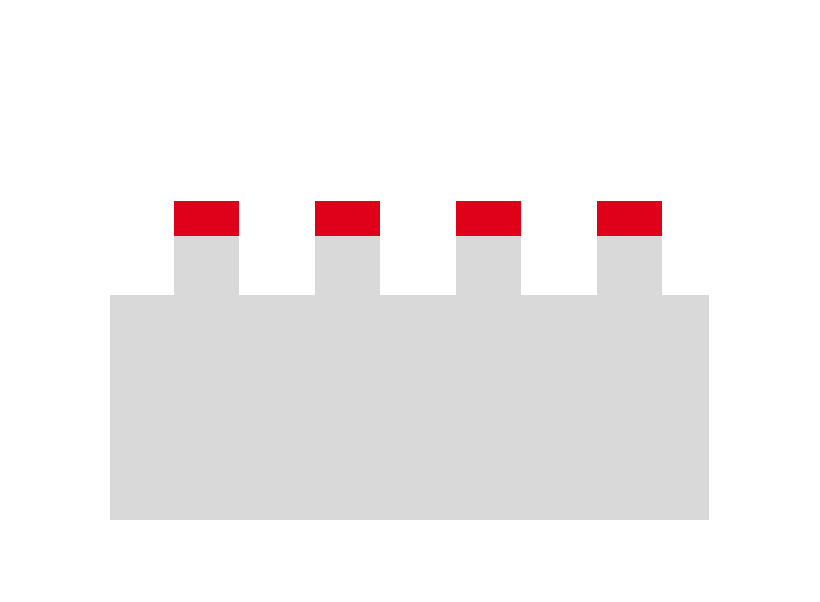

When letterpress is used as a print method, the printing elements are visually raised from the printing plate. The raised design is covered with ink and then pressed onto the paper or substrate. For this reason, letterpress is also referred to as a direct printing method. Even today, the most common form of letterpress is book printing, also known as the flexographic process, which is particularly common in the packaging industry. Flexography is used for printing on paper, cardboard, and plastics.

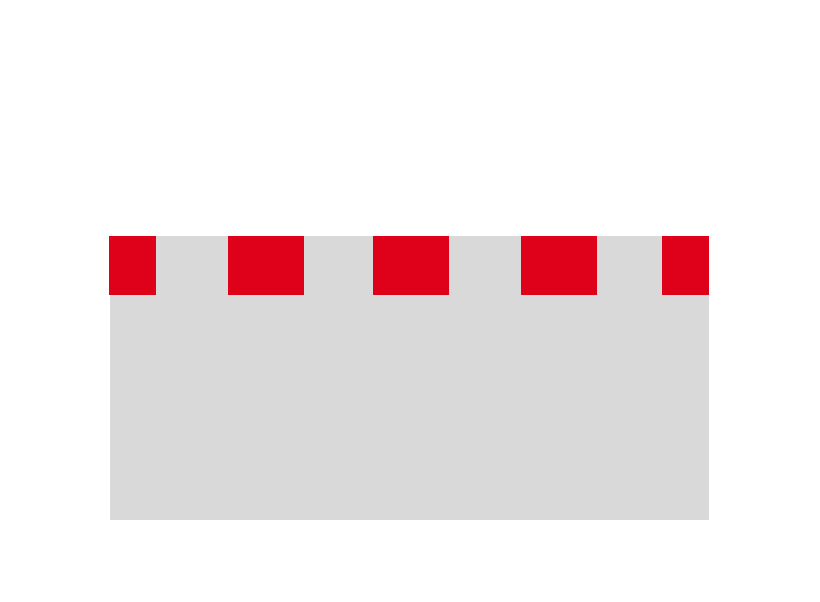

In intaglio printing, the desired image is etched into the printing plate, creating indentations, also known as wells. Then, the entire printing plate is inked, and the excess ink is scraped off with a so-called doctor blade – a polished steel strip – so that only the ink remains in the wells. The image is then transferred directly onto the printing object with pressure and a printing cylinder. Intaglio is thus also a direct printing method.

Intaglio is a highly versatile printing method, especially used in rotary printing, such as magazine printing. Although intaglio has lost market share due to declining editions, it is still used in various fields such as the production of high-quality images in magazines, banknotes, wallpapers, decorative papers, stamps, maps, art, as well as printing on clothes and textiles.

Planography is as it sounds: a printing method that uses flat surfaces without elevations or etchings. Instead, the method is based on a chemical principle where the ink carrier is chemically treated before printing. The fat-based ink then adheres to the treated surface and is repelled on the rest. The print is then transferred to the desired substrate via a rubber blanket. Planography is considered an indirect printing method.

The great advantage of planography is that multiple colors, as well as double-sided printing, are possible in one printing run. A popular example of planography is offset printing, which is often used for books, newspapers, and magazines. Planography is also suitable for the production of art prints, posters, product packaging, and promotional materials.

Here comes the printing method we use at Hot Screen: screen printing! Serigraphy means that ink or dye is pressed through a fine-mesh screen onto the material to be printed. Areas where no ink should be printed are covered with a stencil. In this way, color layers are transferred to the substrate until the desired print motif is created.

Serigraphy is a highly versatile printing method that enables printing on various materials, surfaces, and shapes. Therefore, this method is excellent for printing on textiles or carriers. Serigraphy requires some expertise to achieve consistent, high-quality results and is therefore often used in a professional context.

In addition to these conventional printing methods, technological development has resulted in a range of innovative methods, including digital printing and 3D printing methods.

Digital printing is, in comparison to the four main printing methods, a relatively new printing method that allows direct printing of digital images on various materials. Here, print data is processed and printed from the computer by a printing machine. This printing method is particularly effective for small editions and personalized prints.

3D printing is a transformative technology that enables the production of physical objects from digital designs. This method is used in a variety of industries, from the automotive industry to medicine.

For the textile industry, there are five basic print methods. At Hot Screen, we focus our production on transfer prints, but here we go through all the methods:

Flex and flock prints are two methods commonly used for personalizing clothing. Both are forms of heat transfers, or plotter prints, where the design is first transferred onto a carrier film before being printed on the fabric. The flex print consists of three layers: a carrier film, a thin, flexible, colored foil, and a hot-melt adhesive that is activated by heat.

When we at Hot Screen refer to flex print, we are referring to one of our products, Flex Heat Transfer. Our Flex transfer has the same properties as the aforementioned foils. It is a thin, stretchable heat transfer that is ideal for functional garments such as sportswear. Additionally, it is OEKO-TEX certified and available in several different colors, including a photographic effect and color gradients.

The flock print is similar to the flex print but uses a fuzzy foil that gives the print a velvety effect.

The digital transfer print is a method where the logotype is first printed with a type of printer on a special transfer paper. Then, the print is applied to the fabric using heat and pressure – as the name suggests, it is also a form of heat transfer.

The printing process with digital transfer prints can be done with various digital printers. Here, a wide spectrum of designs can be selected and easily printed on the transfer material, but their quality and resolution depend heavily on the printer used. This print method is less wash-resistant than other methods and is therefore more suitable for hobby use.

The screen print is a traditional print method that stands out for its durability and high quality. The ink or dye is pressed through a fine mesh screen onto textiles or substrates. Each color is applied layer by layer, making the screen print ideal for large editions. It can be either a direct print method, where the color is pressed directly into the fabric, or onto a carrier – like the case at Hot Screen.

When applying digital direct prints on textiles, also known as Direct to Garment or DTG printing, special textile inks and inkjet technology are used. This is similar to a regular inkjet printer but is specially designed for textiles.

This print method requires no foils and can deliver high-quality results from small to large volumes. The printing process offers a wide color spectrum and can be printed in CMYK, RGB, and white. However, not all colors in the Pantone color scale are possible.

With this method, the result can vary significantly depending on the fabric. Digital direct prints are especially suitable for cotton textiles. Additionally, digital direct prints is suitable when complex designs need to be printed. The results are typically characterized by their long durability and precision.

The sublimation print differs from the other print methods. Here, we also talk about a form of heat transfer, where the design is first printed on a special transfer paper and then transferred to the fabric using heat. However, the special feature of this method is that the ink is converted to gas when heated and penetrates the textile fibers. This method allows for vibrant colors and high wash resistance but can only be applied to certain fabrics.

From the traditional high-pressure technique to the modern digital print technique, the world of print methods is multifaceted and constantly changing. Whether it is 3D prints that pushes the boundaries of what is possible or the conventional print methods that still have their place, each technique has its unique characteristics and serves a specific purpose.

About this article

Written by:

Christin

Categories

Related articles

Transfer print – everything you need to know about the popular clothing print

Read more

About this article

Written by:

Christin

Categories

Related articles

Transfer print – everything you need to know about the popular clothing print

Read more

Prints on workwear? Choose the heat transfer Stark!

Products

Tips & Tricks

The plotter print is a variation of our product Stark Heat Transfer.

Products

Learn more about the various print methods in the textile industry.

Print methods

Mon-Thu: 08.00-16.30

Fri: 08.00-15.30

Följ oss!

When you archive an article, it disappears from your webshop and is no longer orderable.

When you activate an article, it disappears from your archive and you can order it again