About this article

Categories

We have three printing machines for clothes, also called heat press or transfer press: Hot 1000e, Hot 2000 and Hot 4000. Each with its own design and different operation (electricity or electricity and compressed air) but with the same high quality, reliability, safety and ergonomics. They are an important part of what we deliver: environmentally certified heat transfers and printing machines for clothes, made of Swedish steel. With these heat presses, we have, among other things, carried out product tests to see how well our heat transfers adhere to garments and what washing and drying degrees they can withstand. So, how do you use the presses?

When you receive your printing machine for clothes from us, it is fully assembled. Remove the plastic and place the heat press where you want it – remember, among other things, that the working height must be suitable and that there are good unloading spaces around the press (for example a rolling table), so that you can achieve a good working flow. The Hot 1000e is a heat press that is only using electricity. Plug the cord into a socket with access to 220V 10AMP slow fuse – this should be a separate group as the entire power is periodically used by the press. Then you turn it on and adjust the temperature, time and pressure – wait for the right temperature and start! It comes with user manuals for all our printing machines for clothes that show you step by step how to carry out an installation. Hot 2000 and 4000 use electricity and compressed air, we will tell you more about this further down.

But first:

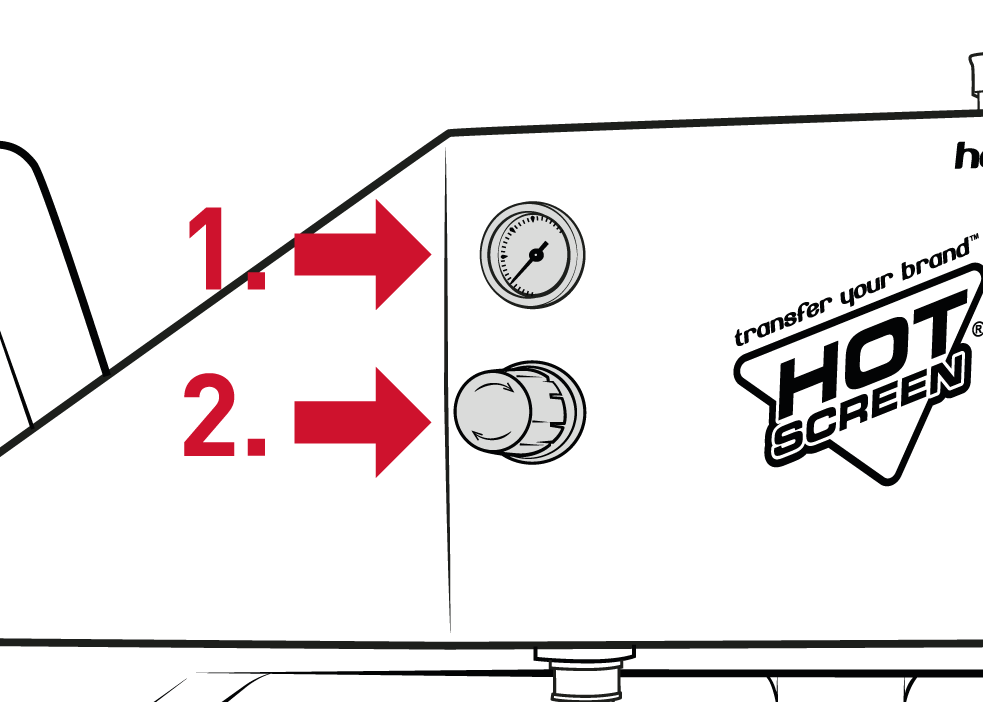

The Hot 1000e adjusts the press pressure automatically based on the selected size of the subplate in the display menu. The user manual shows measured values in kg/cm2 for each size. On our Hot 2000 and 4000 heat presses, the pressure is adjusted manually via the pressure regulator on the side – and it is important to get it right! The pressure is increased when the press is in working position, that is: when the heating plate is pressed down against the subplate. If you need to lower the pressure, raise the heating plate and turn down the pressure completely. Then you lower the heating plate into working position and set the desired pressure. This is to avoid a difference in the pressure setting.

Our Hot 2000 and Hot 4000 printing machines for clothes use compressed air from compressors. For this to work, the heat presses need to be fed with clean air. Water accumulates in the compressor’s pressure tank, so be sure to empty it continuously. If you have bought your compressor from us, do the following:

We have a lot of smart, useful accessories for our printing machines for clothes, here are some tips:

About this article

Written by:

Christin

Categories

Related articles

Sustainable Prints on Workwear

Read more

This is how you use our plotter transfer

Read more

Printing on Polyester? Here's How!

Read more

Club clothing with a sustainable print

Read more

We have carried out measurements on our printing machines for clothing to ensure recommended pressure based on the size of the subplate, so that the application of the heat transfer will be optimal. Here you will find the measured values and recommendations.

About this article

Written by:

Christin

Categories

Related articles

Sustainable Prints on Workwear

Read more

This is how you use our plotter transfer

Read more

Printing on Polyester? Here's How!

Read more

Club clothing with a sustainable print

Read more

Prints on workwear? Choose the heat transfer Stark!

Products

Tips & Tricks

The plotter print is a variation of our product Stark Heat Transfer.

Products

Learn more about the various print methods in the textile industry.

Print methods

Mon-Thu: 08.00-16.30

Fri: 08.00-15.30

Följ oss!

When you archive an article, it disappears from your webshop and is no longer orderable.

When you activate an article, it disappears from your archive and you can order it again